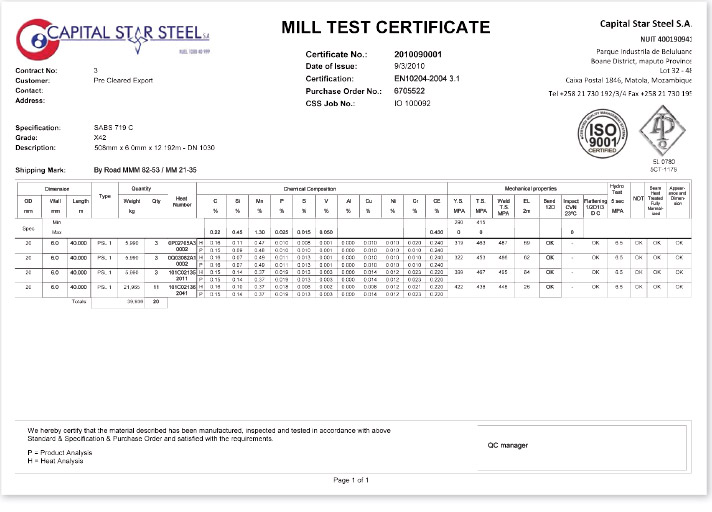

Hydrostatic Test Certificate

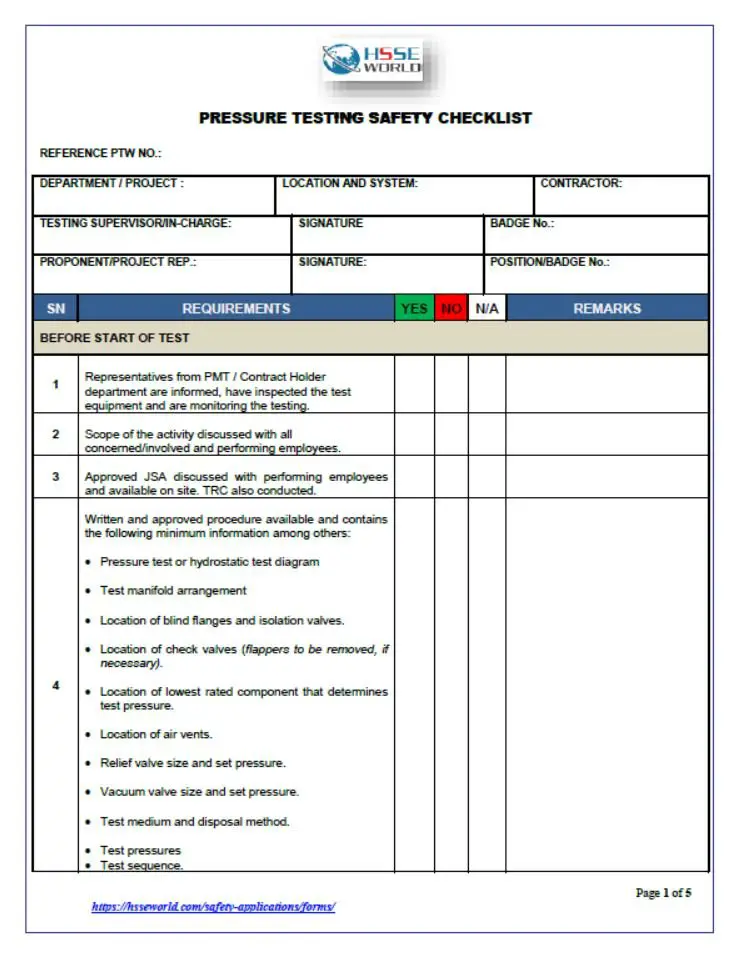

The tests generally are performed to detect any flaws safety issues leaks or cracks.

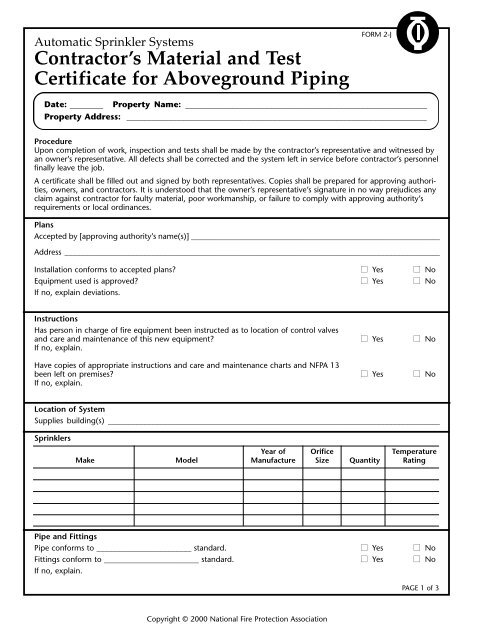

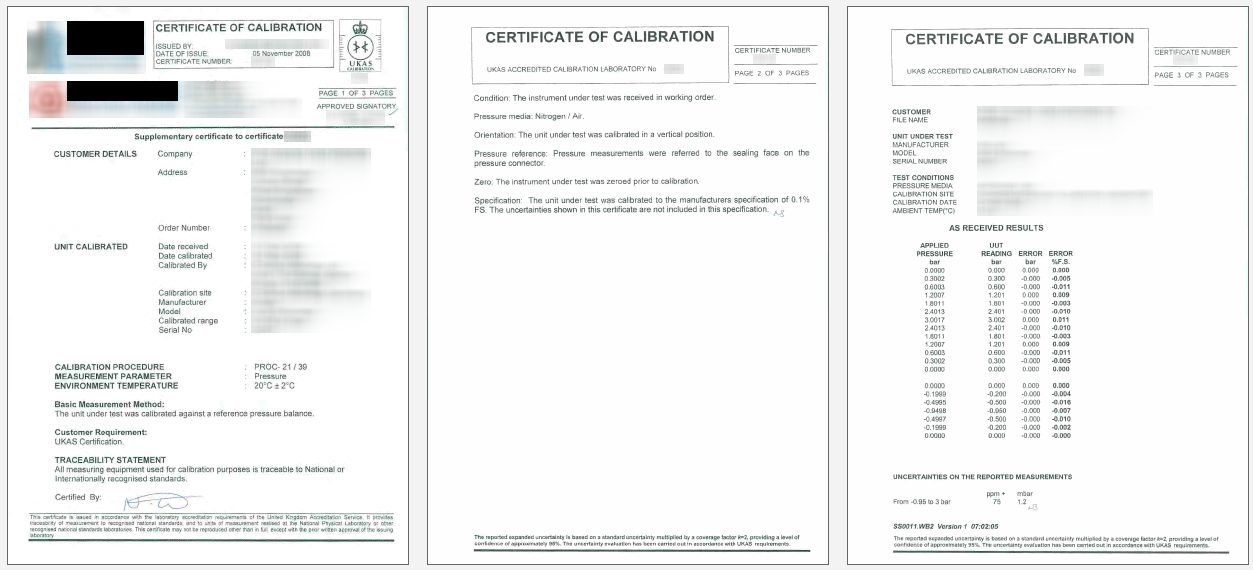

Hydrostatic test certificate. Plus required test pressure. Test results test date. Intensifier unit standard. No external leakage is permissible from any joints for the duration of the test.

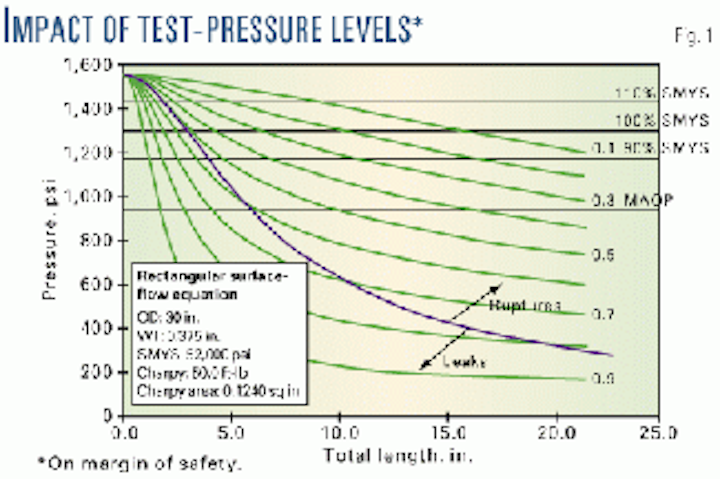

If normal pressure 8bar test at 12 bar. Hydrostatic certification is the standard test required every five years for compressed gas canisters used by divers fire departments and medical personnel among others to be requalified for use. Hydrostatic testing is performed on fluid pressure vessels such as holding pipes pipelines cylinders and tubes. If you look at the simplest form of a hydrostatic pressure test certificate it will state a medium plus a pressure then go on to declare that on a certain date that the part whether it is a hose pressure vessel or whatever was taken up to the pressure with no leakage or permanent deformation.

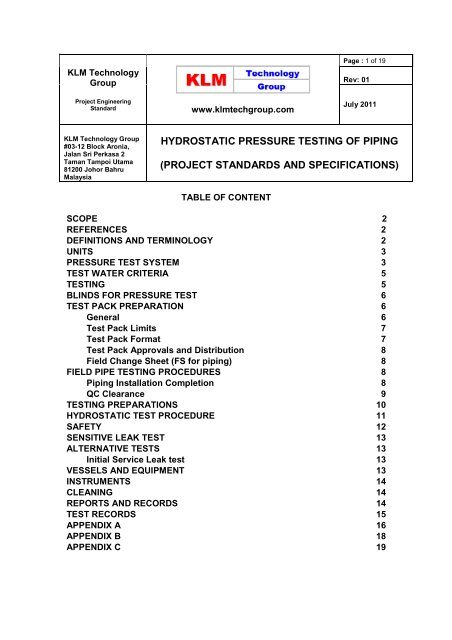

These tests are critical to evaluate the condition and performance of the vessels. Gauge pressure calculation see section 424 elevation difference between gauge and high point. Hydrostatic pneumatic. Pipeline welding inspection school providing cpwi hydrostatic testing chti advanced field inspection cafi pipeline autoweld inspection cpai and cwi certifications.

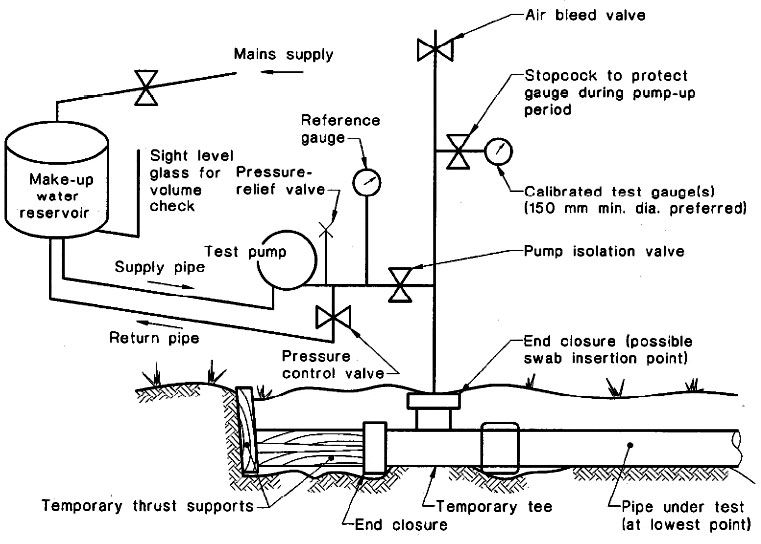

A hydrostatic test is a way in which pressure vessels such as pipelines plumbing gas cylinders boilers and fuel tanks can be tested for strength and leaks. This testing is required by federal law and governed by the us. The test involves filling the vessel or pipe system with a liquid usually water which may be dyed to aid in visual leak detection and pressurization of the vessel to the specified test pressure. Period of test min 30 mins test method co2 air test pressure min 4 bar sufficient room to attach pumpset minimum 250mm required yes na has the manifold label been fitted.

Hydrostatic test certificate reference pressure gauge number. Maximum working pressure a. The test pressure must be maintained for 1 minute both fluid chambers. Test requirements required test pressure.

Pressure test certificate site details site name date address reference technician floor level pipe reference manifold reference. Pumps must be capable of withstanding a test pressure equivalent to 15 x the normal operating pressure maximum. Equals required gauge pressure. Hydrostatic test pumps.

It is vital to describe the part with a serial number even if you engrave something as you might on a first off from a batch of hoses.