Lean Standard Work Template

Find a free template for everything here.

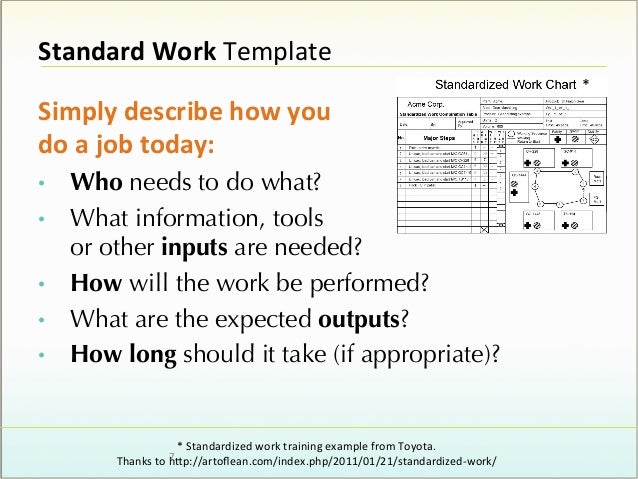

Lean standard work template. Looking for templates for crafts scrapbooking or any other project. For a better understanding of these templates and an overview of lean six sigma check out our free lean six sigma yellow belt training green belt training lean training or black belt training. Improving standardized work is a never ending process. Leader standard work definition example template and advice.

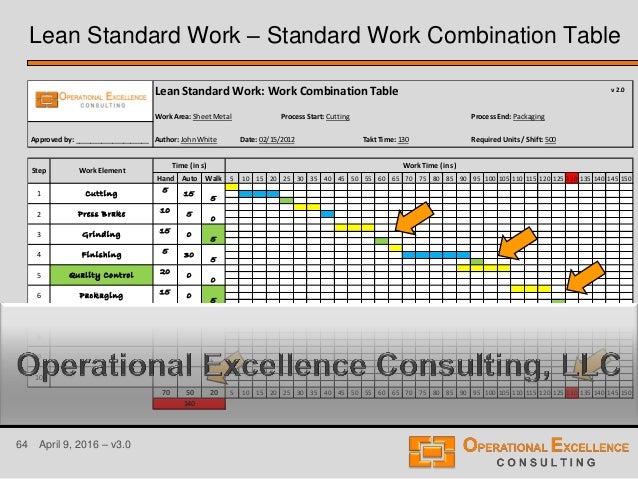

Find a free template for everything here. Lean standard work template excel lean standard or standardized work training module 64 638 looking for templates for crafts scrapbooking or any other project. Leader standard work is a critical step in ensuring that the lean culture in your organization prospers. It helps companies reach their improvement targets but also provides a stable reasonable working environment for frontline employees.

Lean standard work template excel lean standard work template 187657. The templates provided here are suitable for yellow green and black belts. The purpose of standardized work according to kaizen express from which this form is taken is to provide a basis for continuous improvement through kaizen. But leader standard work is dependent on a few things.

Please feel free to share or modify these templates but please do not remove our url or logo to better help you apply lean. Standardized work is one of the most powerful but least used lean tools. Make your work simpler with templates. By documenting the current best practice standardized work forms the baseline for kaizen or continuous improvement.

As the standard is improved the new standard becomes the baseline for further improvements and so on. It can be used by web. Lean training certification. Lean six sigma glossary.

Online lean six sigma training. You may also be interested in. The template is a framework or blueprint which can be used for creating a generic class or function. It locks in gains and provides a foundation for future advances.

Both approaches originated in the manufacturing industry lean by toyota and six sigma by motorola but today they are used to improve many processes within an organization from customer support to administration.