Pile Driving Template

:max_bytes(150000):strip_icc()/pile-driving-construction-site-no-body-687943904-7b75bb8c65d243c797fc544f0d2ed543.jpg)

A two level template or wale system is generally suggested.

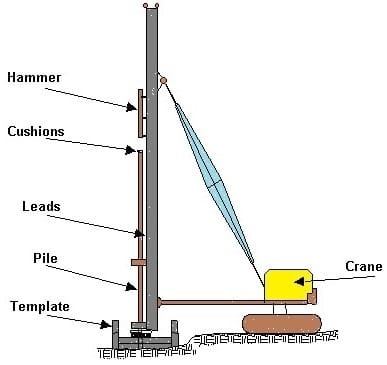

Pile driving template. The geometry of the pile section may cause plugging of the pilings in most cohesive soil strata and also in certain dense granular strata. Usually each element of the panel is driven a few meters into the ground in a specific sequence. Olmsted lock and dam pile driving template. For permanent walls ie.

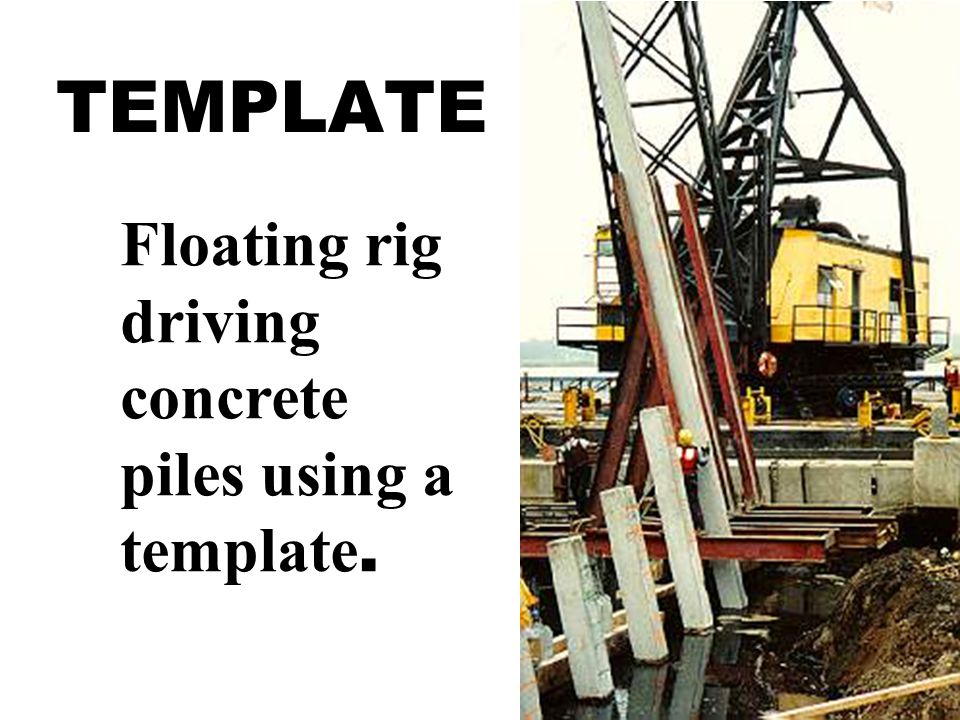

With extensive track record in designing tailor made tools for offshore pile driving twd engineers are well equipped to respond to the various challenges of pile driving operations and develop optimal project specific solutions ranging from robust sub sea templates to highly efficient monopile grippersd. Driving methods gaining or loosing. Pile cutoffs shall be made to the elevation shown on the plans or as established by the eic. The pile section chosen be compatible with the prevailing soil conditions.

Mark the driving template for each pile or pair of piles. Group sequence makemodel driven length pdes pult type top elev. Insure that the sheets are properly interlocked when set. Weight unit weight max equiv.

Improper interlocks become the weak links and result in job delays andor failures. Any pile sections remaining above ground shall be painted in accordance with the plans. Cast in place pile casings shall be dry before concrete is placed. Pnd was retained to design the pile driving system used to construct combi wall and pipe pile foundations for the new olmsted lock and dam at olmsted illi nois.

Therefore it follows that. How to drive steel sheet piles ape pile driving school author. Type rated energy tip elev. Impact hammers things to consider.

Length area ram weight cut off elev. All cavities created by the pile driving shall be backfilled. Underground car parks basements. In addition to driving a straight wall a template or guide system will also aid in keeping sheet pile plumb when excessive driving conditions exist or when an obstruction is encountered.

This project is another application of in the wet construction favored by the corps of engineers. This method consists in erecting a panel inside a stiff template preferably a two level template before driving the sheet piles. Upper template should be substantial fraction of the pile length. Whether you are driving concrete steel or wood piles any number of problems are common.

This allows for wall adjustments to be made during the setting phase insuring that the sheets are located properly for cell closure. Stroke cut off length required driving resistance max speed ground elev. The driving force required is a function of the soil properties. Pile driving is often a cost effective and time efficient method of driving support posts piles into the earth.

:max_bytes(150000):strip_icc()/pile-driving-work-at-construction-site-1127908936-0686e533304344d5ae6c627e44087bc0.jpg)