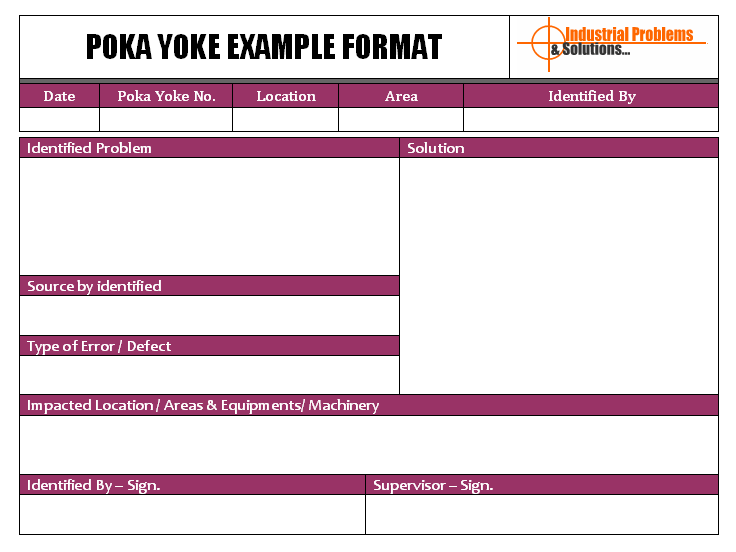

Poka Yoke Template

This technique is called poka yoke and was born out of the toyota production system.

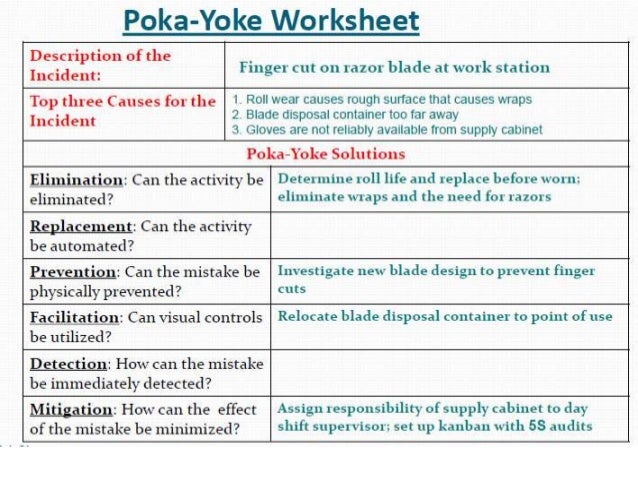

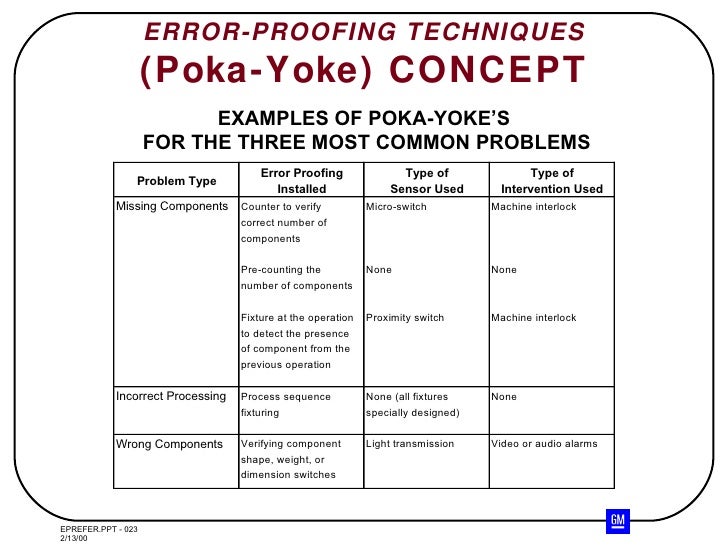

Poka yoke template. Analysis of customer complaints also reveals activities which are in need of mistake proofing in order to achieve a zero defect level of working. In this technique the system eliminates errors or make it impossible for errors to happen. Poka yoke japanese for mistake proofing which owes its genesis to the toyota production system the standard for manufacturing excellence throughout the world offers some principles that may be applied to reducing spreadsheet defects. Poka yoke is a japanese word which means mistake proofing and it is explained in this article with examples.

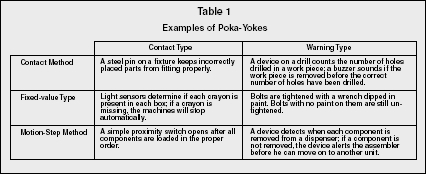

We can see many examples of poka yoke in our daily life like specific design of sim card they are explained in the later part of this article. What is poka yoke. Poka yoke techniques of mistake proofing are applied to these processes in order to lower the ratings of occurrence andor detection. To avoid yokeru inadvertent errors poka.

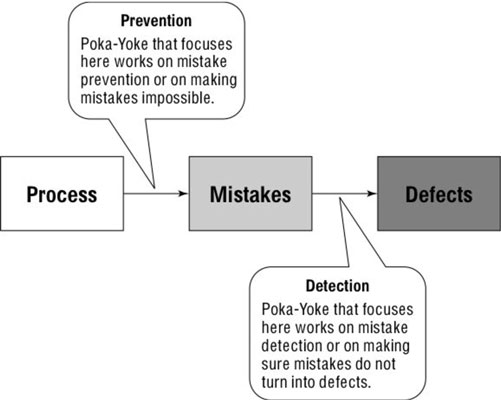

Poka yoke is a method to prevent and resolve defects during the production process eliminating the need for quality control after the process. Any addition to a process which is included to change the behavior of the person operating the process with the intention of reducing mistakes can be referred to by the concept poka yoke. At its core poka yoke is extremely simple. The interlock serves to prevent unintended movement of the car.

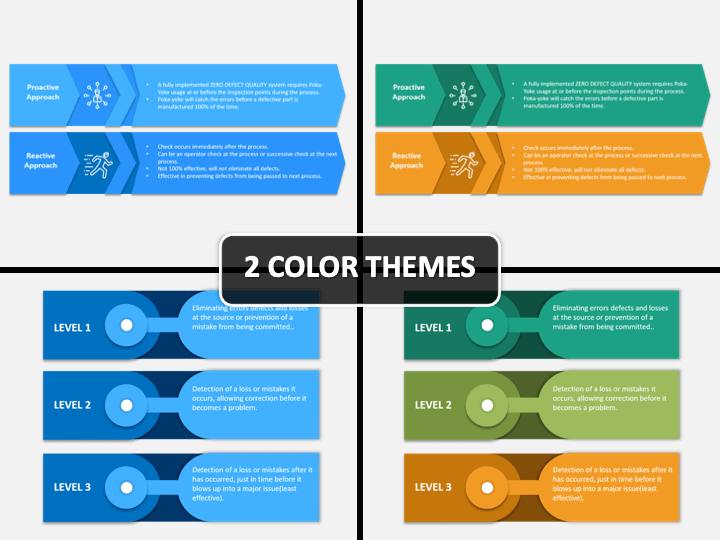

Developed by toyota motors as a tool to achieve zero defects. A simple poka yoke example is demonstrated when a driver of the car equipped with a manual gearbox must press on the clutch pedal a process step therefore a poka yoke prior to starting an automobile. Often referred to as error proofing poka yoke is actually the first step in truly error proofing a system. Originally called baka yoke idiot proof but recognized that this label could offend workers so changed to poka yoke mistake proofing one serious obstacle to extending equipment life is the unexpected failure that occurs as a result of operating or repair errors.

Poka yoke is a quality assurance technique the aim of poka yoke is to eliminate defects in a product by preventing or correcting mistakes as early as possible. Poka yoke can also be applied to service based organizations.