Ppap Documents Template

Easy to use ppap forms in excel production part approval process forms per aiag 4th ed.

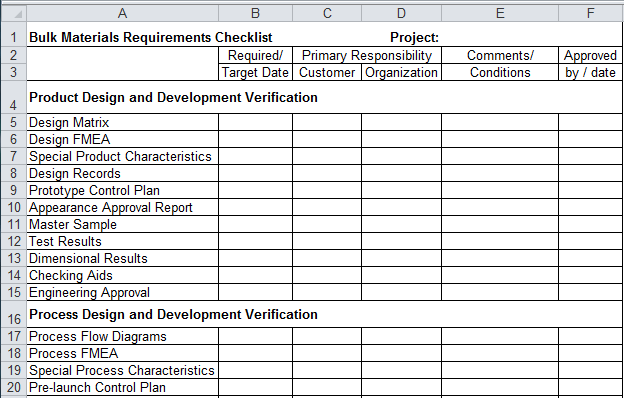

Ppap documents template. This ppap documents checklist contains a ppap submission assessment for quality managers to evaluate their performance of the ppap and maximize opportunities for continuous improvement. Below is a list of all the documents needed to complete a ppap please click each one to learn more about it. The 18 documents or elements of ppap are. Ppap documents with excel templates.

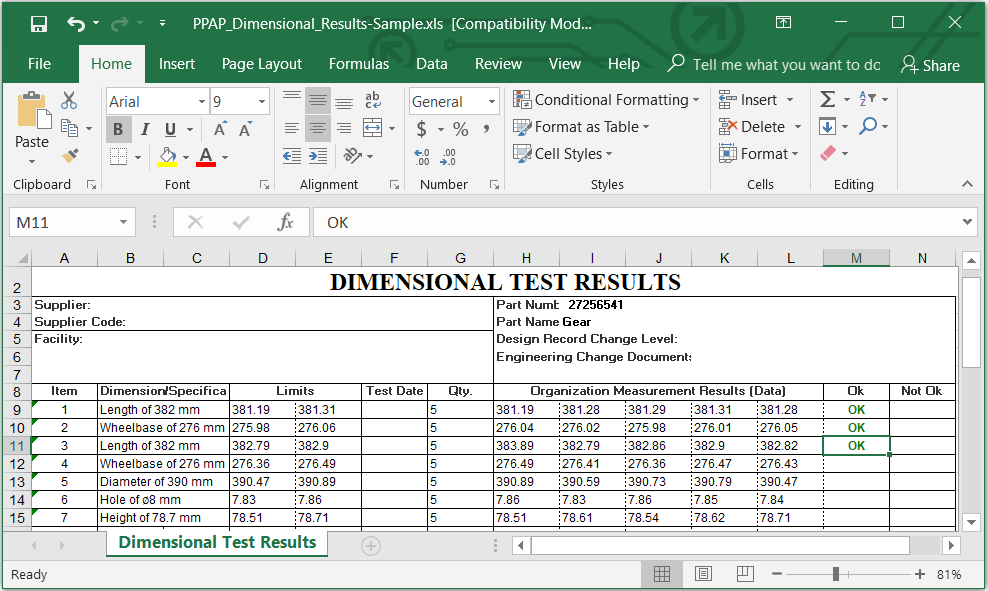

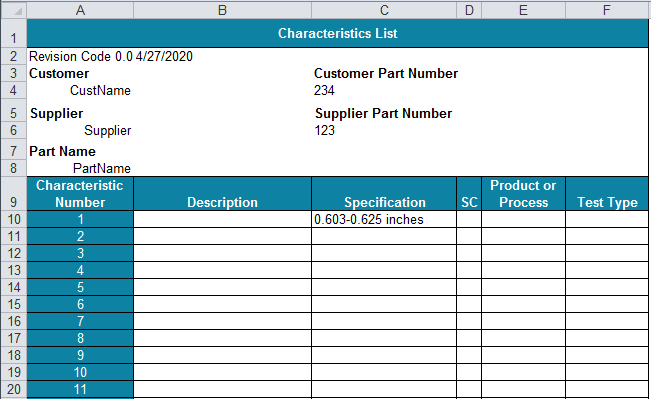

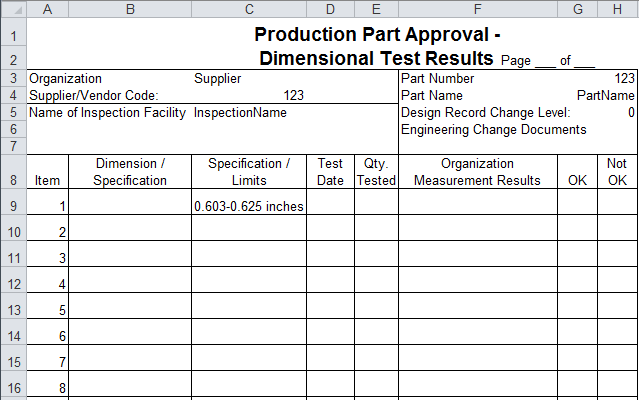

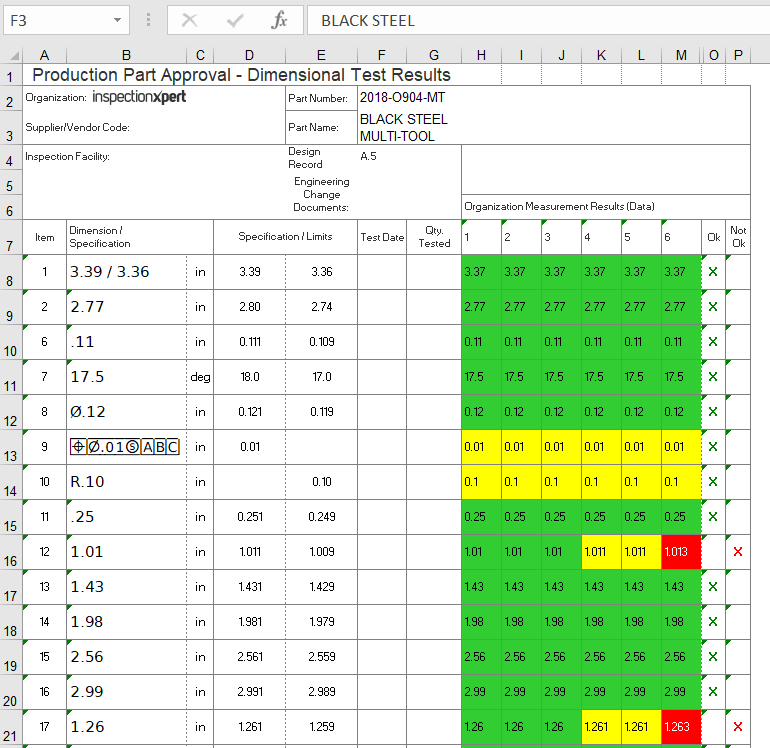

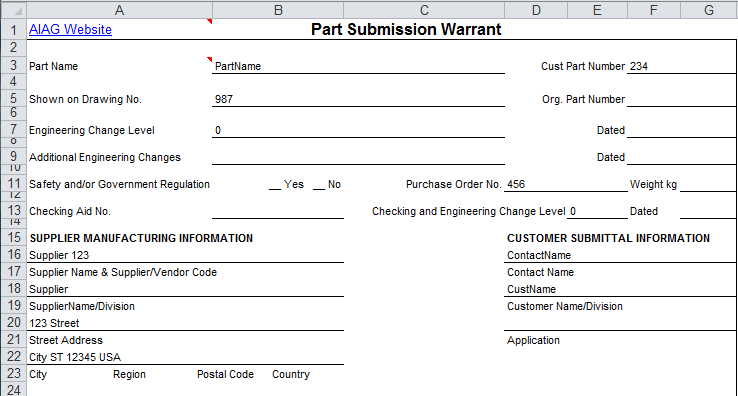

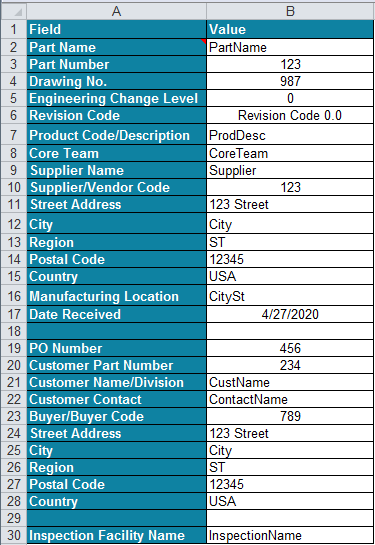

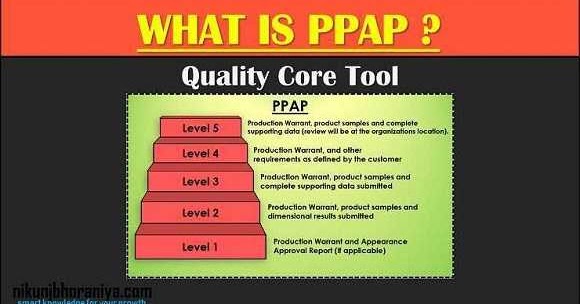

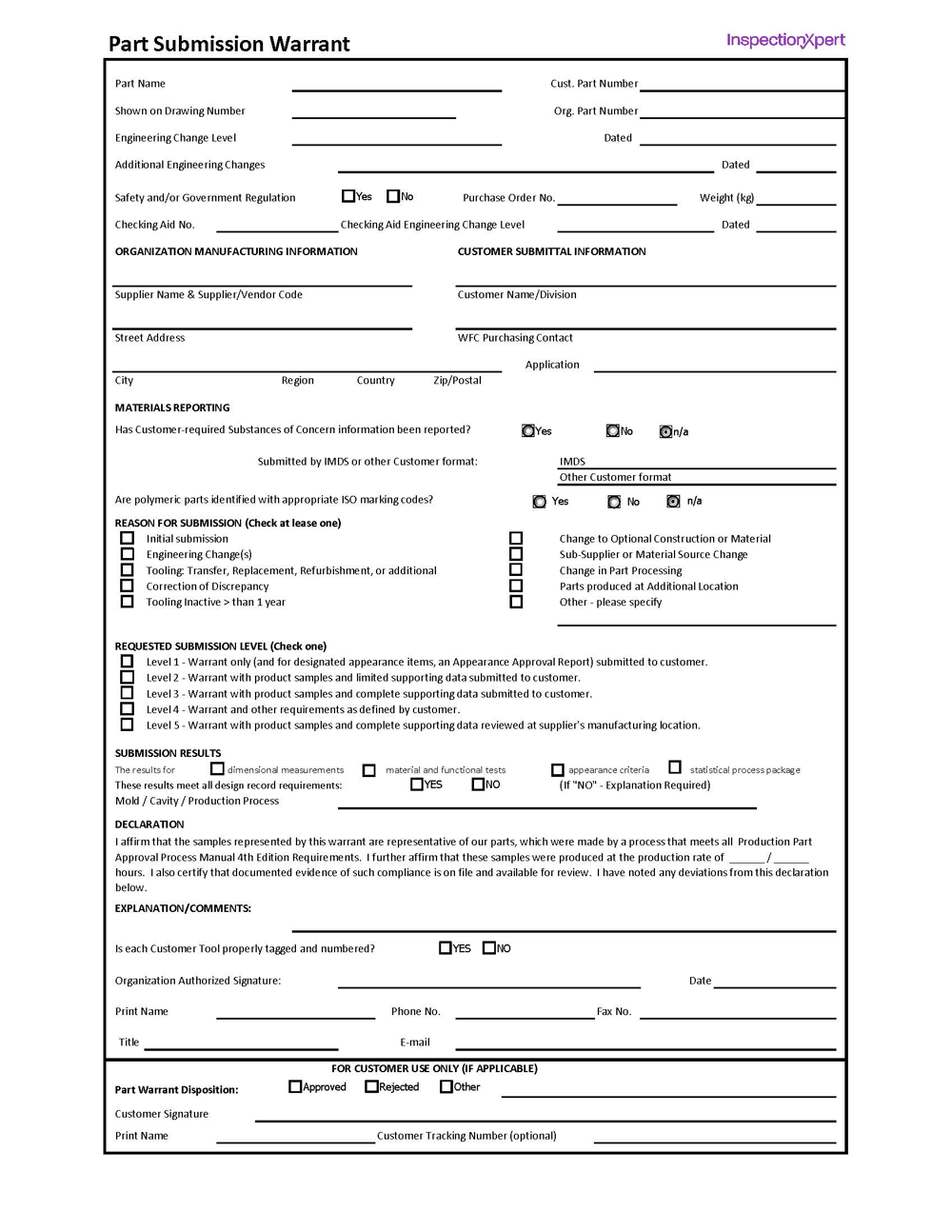

Engineering approval if required 04. Process flow diagram pfd 06. Level 1 part submission warrant psw only level 2 psw with product samples and limited supporting data level 3 psw with product samples and complete supporting data. Measurement system analysis studies msa dimensional results.

This site includes ppap information different level of ppap that can be requsted examples of submissions training providers and a checklist to make sure you your production part approval process is correct. Introduction to production part approval process ppap production part approval process ppap is a valuable tool for establishing confidence in component suppliers and their production processes. According to the aiag ppap manual all elements should be completed. Part submission warrant psw design records.

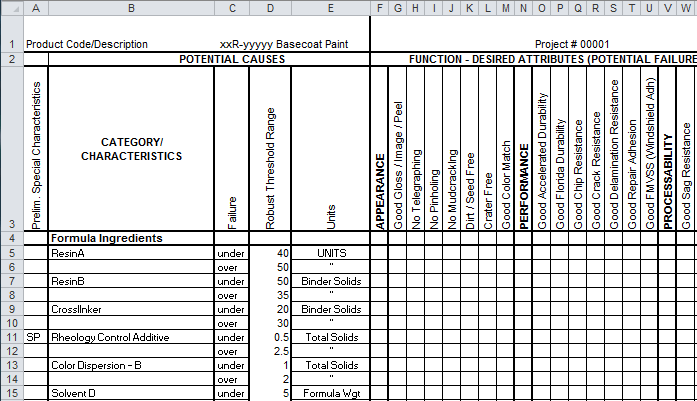

Process failure modes and effects analysis pfmea 07. In todays competitive manufacturing environment controlling cost and maintaining a high level of quality have become vital to a companys success. Part submission warrant psw design records authorized engineering change note documents. The aiag automotive industry action group has developed a variety of standard forms.

A ppap documents checklist aims to ensure the accurate and timely submission of production part approval process documents. On this site you will find lots of information on building or updating a complete ppap. The production part approval process ppap is used in the automotive supply chain to establish confidence in component suppliers and their production processes by demonstrating that all customer engineering design record and specification requirements are properly understood by the supplier and that the process has the potential to produce product consistently meeting these requirements. However this manual procedure could be very stressful and time consuming while you can finish this fai tasks more easily and efficiently with our ppap fai software qa cad 2019.

Authorized engineering change note documents. Design failure modes and effects analysis dfmea 05.