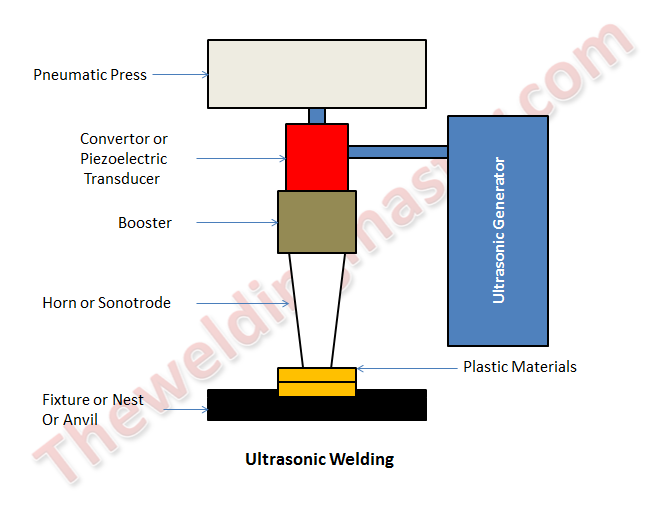

Ultrasonic Welding Diagram

It is most commonly used to weld thermoplastic materials and dissimilar materials.

Ultrasonic welding diagram. After reading this article you will learn about the setup for ultrasonic welding with the help of a diagram. And what actually happens during the welding process depends on the nature of the materials. Ultrasonic welding is an industrial technique whereby high frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid state weldit is commonly used for plastics and metals and especially for joining dissimilar materialsin ultrasonic welding there are no connective bolts nails soldering materials or adhesives necessary. Today we will learn about ultrasonic welding principle working equipments application advantages and disadvantages with its diagram.

Metal with a thin section can also be welded with usw. The components are bonded by cohesive or form fit joints after a short hold. Ultrasonic means those vibration waves which have frequency above the normal hearing range. Medical devices such as catheters valves filters and.

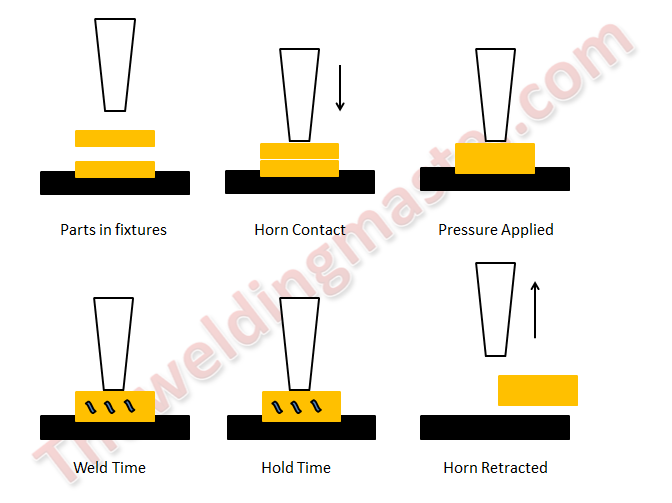

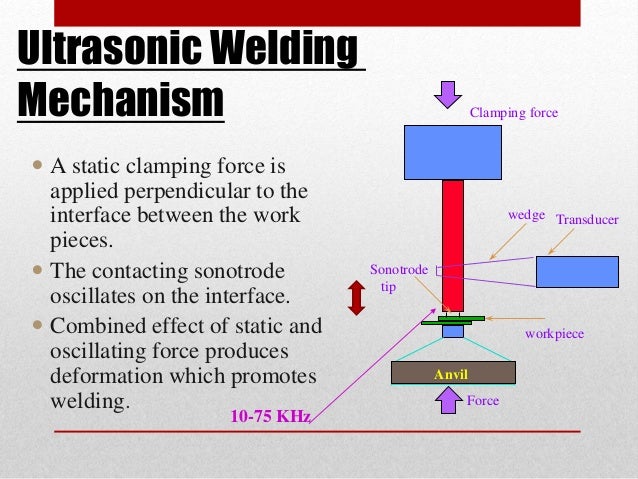

The plastic becomes soft and starts melting. That mechanical motion along with applied force creates frictional heat at the plastic. Process and quality characterization for ultrasonic welding of lithium ion batteries by seungjae lee a dissertation submitted in partial fulfillment of the requirements for the degree of doctor of philosophy mechanical engineering in the university of michigan 2013 doctoral committee. Ultrasonic welding usw is a welding technique that uses ultrasonic vibration of high frequency to weld the two pieces together.

Ultrasonic welding of plastics is used widely in making electronics medical devices and car parts. Ultrasonic welding is a welding process in which ultrasonic waves or vibrations are used to generate heat for welding. For example ultrasonic welding is used to make electrical connections on computer circuit boards and assemble electronic components such as transformers electric motors and capacitors. Ultrasonic welding of thermoplastic materials is a weld technology utilizing mechanical vibrations to generate heat due to molecular friction.

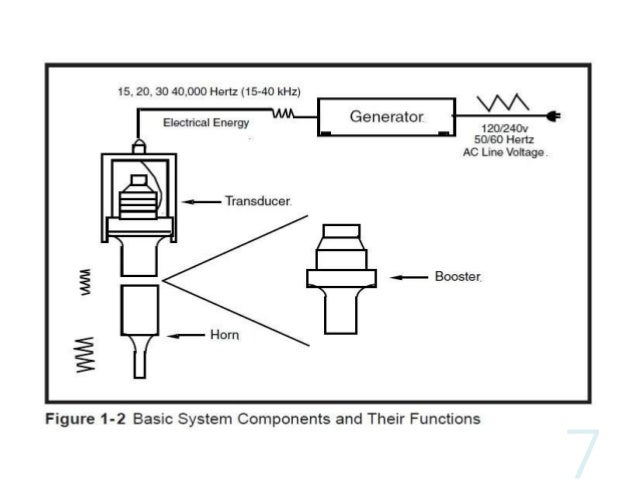

It is accomplished by converting high frequency electrical energy into high frequency mechanical motion. Ultrasonic plastic welding is the joining or reforming of thermoplastics through the use of heat generated from high frequency mechanical motion. In metals the ultrasonic vibrations are delivered parallel to the plane of. These vibrations excite the molecules in the plastic so that they start moving.

Ultrasonic welding working parts advantages and applications ultrasonic welding.